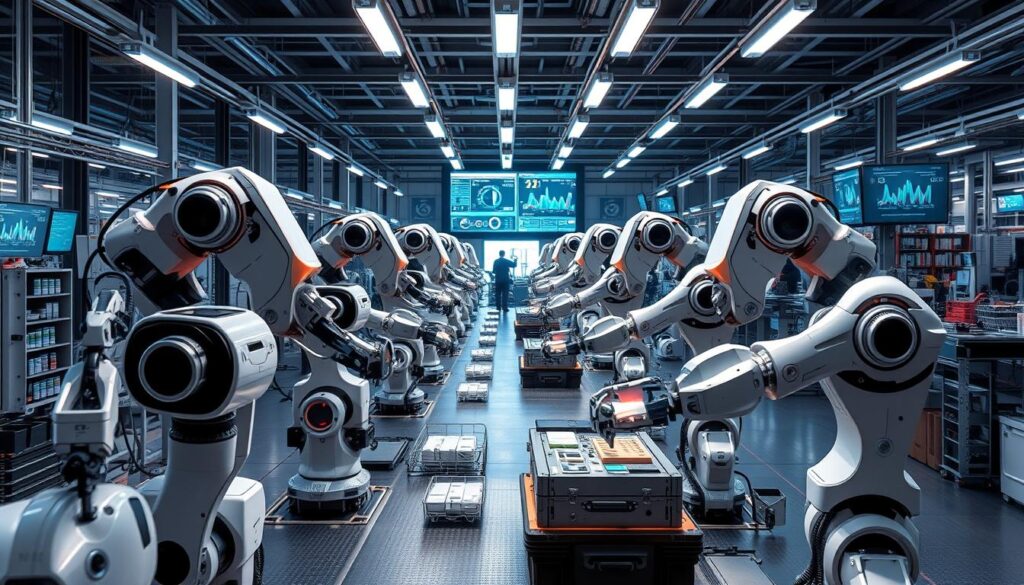

Robotics is leading the change in modern manufacturing, known as Industry 4.0. This new era combines advanced technologies like automation, artificial intelligence, and the Internet of Things. These technologies are changing how we make things and run factories.

Robotics is key to this technological leap. It brings huge gains in efficiency, productivity, and competitiveness to manufacturers. With tools like programmable logic controllers and machine vision, factories are becoming smarter and more automated.

Artificial intelligence and machine learning are at the heart of this change. They help manufacturers improve their operations, predict when things need fixing, and check quality better. The Internet of Things makes factories connected, using real-time data for better decisions and improvements.

The future of manufacturing looks bright with robotics and Industry 4.0. New trends in automation and advanced robotics systems will make things even better. The mix of human skills and robot abilities will change the manufacturing world, leading to more innovation and growth.

Key Takeaways

- Robotics is the driving force behind the Industry 4.0 revolution in manufacturing

- Automation and advanced technologies, such as artificial intelligence and the Internet of Things, are transforming the manufacturing industry

- Smart factories and collaborative robots are enhancing productivity, efficiency, and competitiveness

- Machine learning applications and predictive maintenance are optimizing manufacturing operations

- The fusion of human expertise and robotic capabilities is shaping the future of manufacturing

The Rise of Robotics in Manufacturing

The manufacturing world is changing fast, thanks to new robotic technologies. Automation and industrial automation are leading this change. They help manufacturers reach new heights of efficiency gains and productivity.

Automation and Efficiency Gains

Robotic systems have changed how products are made, packaged, and moved. They cut down the time and effort needed for many tasks. This leads to efficiency gains that save money and improve quality.

Increasing Productivity and Competitiveness

Industrial automation has also boosted productivity. Robots work non-stop, helping manufacturers make more and meet demand better. This makes companies more competitive globally, helping them adapt to market changes.

“Robotics has transformed the manufacturing landscape, empowering companies to streamline their operations and achieve unparalleled levels of productivity and efficiency.”

Robotics are becoming more common in manufacturing, leading to big changes. The rise of robotics is key to Industry 4.0. It’s making factories smarter and changing how goods are made.

Robotics in Manufacturing: The Engine Behind Industry 4.0

Robotics is leading the charge in Industry 4.0, changing how we make things. It combines advanced robotics, smart tech, and data to create smart factories. These factories are more efficient and can adapt quickly.

Robotics is changing the game in manufacturing. It brings better automation, more productivity, and lower costs. This makes factories more competitive and saves money.

One big plus of robotics is how it boosts efficiency and productivity. Robots work faster and more accurately than humans. This lets factories run smoother and produce more.

| Metric | Increase with Robotics |

|---|---|

| Productivity | Up to 30% |

| Efficiency | Up to 25% |

| Cost Savings | Up to 20% |

Robotics also works well with smart tech like IoT and AI. This makes factories more adaptable and quick to respond. This helps them stay competitive and meet changing market needs.

Robotics is key to Industry 4.0. It combines advanced tech, data, and automation. This leads to more efficient, agile, and responsive manufacturing in the future.

Industrial Automation and Smart Factories

The world of industrial automation and smart factories is changing how we make things. It helps businesses make better products, check quality, and move materials around more easily. New tech like programmable logic controllers (PLCs) and machine vision, plus automated guided vehicles (AGVs), are key to this change.

Programmable Logic Controllers and Machine Vision

PLCs are the core of industrial automation. They handle complex tasks and work with many sensors and machines. This lets them control things in real time and make smart choices.

Machine vision systems add to this by checking products and spotting problems. They use advanced tech to make sure products are good quality.

Automated Guided Vehicles and Material Handling

AGVs are changing how we move things in smart factories. They drive around on their own, carrying goods and parts. This cuts down on the need for people to move things, making things run smoother.

By using AGVs, factories can make more, cut down on mistakes, and make their supply chain better.

| Technology | Key Benefits |

|---|---|

| Programmable Logic Controllers (PLCs) |

|

| Machine Vision Systems |

|

| Automated Guided Vehicles (AGVs) |

|

By using these smart technologies, factories can do better. They can make more, improve quality, and move things around better. This makes them more competitive and efficient.

Collaborative Robots and Human-Robot Collaboration

The world of manufacturing is changing fast. Robots are now working alongside humans in new ways. These robots, called cobots, are different from the old kind. They work safely with people, making jobs better and safer.

Cobots have special sensors and smart programs. They do tasks that are hard or risky. This lets humans do more creative and important work.

Working with robots brings many benefits. Cobots can lift heavy things and do precise tasks. This makes work safer and more efficient. It also makes people happier at work because they can use their skills better.

| Benefits of Collaborative Robots | Benefits of Human-Robot Collaboration |

|---|---|

|

|

The future of work is looking bright. With collaborative robots and human-robot collaboration, jobs will be better and more fun.

“The future of manufacturing lies in the seamless integration of humans and robots, where each can leverage their unique strengths to drive innovation and success.”

Artificial Intelligence in Manufacturing

The manufacturing world is changing fast, thanks to artificial intelligence (AI) and machine learning (ML). These technologies are making factories work better, leading to more efficiency, productivity, and quality.

Machine Learning Applications

Machine learning is changing how we make things. It uses data to find patterns and make smart decisions. This helps in many ways, like keeping equipment running smoothly and checking product quality.

| ML Application | Benefits |

|---|---|

| Predictive Maintenance | Anticipating equipment failures, reducing downtime, and optimizing maintenance schedules. |

| Quality Control | Detecting defects, improving product consistency, and minimizing waste. |

| Supply Chain Optimization | Forecasting demand, optimizing inventory, and streamlining logistics. |

Predictive Maintenance and Quality Control

AI and ML are big in predictive maintenance and quality control. They look at data to spot problems before they happen. This means less downtime and better products.

“Artificial intelligence and machine learning are transforming manufacturing, empowering businesses to achieve new levels of efficiency, productivity, and quality control.”

The future of manufacturing looks bright with AI and ML. We can expect better production, maintenance, and quality. The possibilities are endless.

Internet of Things (IoT) in Manufacturing

The manufacturing world is changing fast with the Internet of Things (IoT). This new technology is making factories smarter and more connected. Now, real-time data is key to better operations, smarter decisions, and clearer supply chains.

Connected Factories and Real-Time Data

IoT is turning factories into connected hubs. Smart sensors and systems work together to share data in real-time. This gives manufacturers deep insights into their operations.

They can use this data to improve their processes and make better decisions. For example, they can keep their equipment running smoothly and fix problems before they happen. This reduces downtime and keeps product quality high.

IoT also helps companies see their supply chains better. They can respond faster to customer needs and avoid stock problems.

| Key Benefits of IoT in Manufacturing | Description |

|---|---|

| Operational Efficiency | Real-time data and analytics help optimize processes, reduce waste, and improve overall equipment effectiveness. |

| Improved Decision-Making | Data-driven insights enable manufacturers to make more informed decisions, leading to enhanced productivity and competitiveness. |

| Enhanced Supply Chain Visibility | Connected factories can better monitor and manage their supply chains, responding more quickly to market demands. |

The Internet of Things is changing the manufacturing world. The connected factory model is becoming more common. It’s driving innovation, excellence, and big changes in the industry.

Robotic Process Automation and Advanced Robotics Systems

In the world of manufacturing, new technologies are changing the game. Robotic process automation (RPA) and advanced robotics systems are leading the way. They make tasks easier, improve efficiency, and help companies stay ahead.

RPA uses software to automate tasks that humans used to do. This frees up people to do more important work. It also cuts down on mistakes and boosts productivity.

Advanced robotics systems are also making a big impact. They have smart sensors and can learn from data. This lets them adjust to new needs and improve quality.

By using RPA and advanced robotics, companies can work better and save money. These technologies are key to the future of manufacturing. They help businesses stay quick, efficient, and ready for change.

“Robotic process automation and advanced robotics systems are the keys to unlocking greater efficiency, productivity, and competitiveness in the manufacturing sector.”

The Future of Robotics in Manufacturing

The manufacturing world is changing fast, and robotics is leading the way. New trends and tech are coming together to change how we make things. Advanced sensors, machine learning, and self-driving systems are at the heart of this change.

Emerging Trends and Innovations

One big thing happening is the rise of robots that can learn on their own. These smart robots can adjust to new situations and work better over time. They can even make decisions without needing a human to tell them what to do.

Also, robots that can move around on their own are changing how we handle materials in factories. These robots can move goods around quickly and accurately. This makes production faster and cheaper.

- Self-learning robots that can adapt to changing environments

- Autonomous navigation systems for material handling and logistics

- Advanced sensors and data analytics to enhance precision and quality control

Another big change is the use of advanced sensors and data analysis for quality control and maintenance. These tools can spot problems early and help fix them before they cause trouble. This keeps products consistent and reduces downtime.

“The future of robotics in manufacturing is all about adaptability, autonomy, and data-driven decision-making. These emerging trends will empower manufacturers to achieve new levels of efficiency, flexibility, and competitiveness.”

As we move forward, these emerging trends and innovations will be key. They will help make manufacturing smarter, more flexible, and more resilient.

Conclusion

The rise of Industry 4.0 has changed the game in manufacturing. Robotics, automation, and smart technologies have made a big impact. They’ve boosted efficiency, productivity, and competitiveness like never before.

We’ve seen how robotics is changing the manufacturing world. From smart machines to robots that work with humans, these technologies are key. They help manufacturers cut costs and stay competitive in a fast-changing market.

Looking ahead, we can expect even more from robotics and automation. Advances in AI, the Internet of Things, and robotic process automation will bring more innovation. By adopting these technologies, manufacturers can lead the Industry 4.0 revolution. They’ll achieve new heights of success in the modern manufacturing world.