In today’s fast-paced business landscape, the ability to effectively manage your supply chain has become essential for maintaining a competitive edge. Enter supply chain automation – a game-changing approach that can revolutionize the way you streamline your logistics, boost efficiency, and cut costs. In this comprehensive guide, we’ll explore the essential steps to automate your supply chain management processes. From inventory tracking and warehouse optimization to leveraging the power of predictive analytics and AI, you’ll discover practical strategies to help your business thrive in the digital era.

Key Takeaways

- Discover the key benefits of automating your supply chain management processes.

- Explore the essential components of a successful supply chain automation strategy.

- Learn how to leverage inventory management systems, warehouse automation, and logistics optimization to drive efficiency.

- Understand the role of ERP integration, demand forecasting, and predictive analytics in supply chain optimization.

- Discover how IoT and AI can enhance visibility, tracking, and intelligent automation in your supply chain.

Understanding Supply Chain Automation

In today’s fast-paced business environment, supply chain efficiency is crucial for maintaining a competitive edge. This is where supply chain automation comes into play, revolutionizing the way organizations manage their logistics and operations. By leveraging advanced technologies, supply chain automation streamlines various processes, from inventory management to transportation logistics, leading to increased efficiency, cost savings, and improved decision-making.

What is Supply Chain Automation?

Supply chain automation refers to the integration of technology-driven solutions that automate and optimize various aspects of the supply chain. This includes automating tasks such as order processing, inventory tracking, transportation scheduling, and warehouse management. By automating these repetitive and manual-intensive activities, organizations can reduce errors, improve response times, and enhance overall supply chain visibility.

Benefits of Automating Your Supply Chain

Implementing supply chain automation can bring about a multitude of benefits for businesses, including:

- Increased Efficiency: Automated processes can significantly reduce the time and effort required to complete tasks, leading to higher productivity and faster turnaround times.

- Cost Savings: Automation can help eliminate manual errors, reduce labor costs, and optimize resource utilization, resulting in substantial cost savings for the organization.

- Improved Visibility: Real-time data and analytics provided by automated systems can enhance supply chain visibility, enabling better decision-making and proactive problem-solving.

- Enhanced Customer Experience: Faster order fulfillment, accurate inventory tracking, and reliable delivery times can improve the overall customer experience, leading to increased customer satisfaction and loyalty.

- Competitive Advantage: By automating their supply chain, businesses can gain a competitive edge by outperforming their rivals in terms of efficiency, cost-effectiveness, and responsiveness.

As the demand for logistics automation continues to grow, organizations that embrace supply chain automation will be well-positioned to thrive in the ever-evolving business landscape.

Key Components of Supply Chain Automation

As businesses strive to streamline their operations and stay competitive, the integration of supply chain automation has become a game-changer. This transformative approach encompasses a range of essential components that work together to enhance efficiency, visibility, and responsiveness throughout the logistics ecosystem.

At the heart of supply chain automation lies robust inventory management systems. These technologies enable real-time tracking of stock levels, automated replenishment, and seamless integration with other business processes. By leveraging the power of data, companies can maintain optimal inventory levels, reduce waste, and respond swiftly to fluctuating market demands.

Complementing inventory management, warehouse automation solutions play a crucial role in streamlining the physical handling and movement of goods. From automated storage and retrieval systems to robotic picking and packing, these innovations enhance productivity, accuracy, and speed, ultimately improving overall supply chain performance.

Alongside inventory and warehouse optimization, logistics automation unlocks new levels of efficiency. Advanced transportation management systems optimize routes, monitor fleet performance, and automate the coordination of shipments, driving down costs and enhancing delivery reliability.

Underpinning these operational improvements are powerful data analytics tools. By harnessing the vast amounts of information generated throughout the supply chain, businesses can uncover valuable insights, forecast demand, and make data-driven decisions to stay ahead of the curve.

The seamless integration of these key components – inventory management, warehouse automation, logistics optimization, and data analytics – forms the foundation of a truly automated supply chain. As organizations embrace this transformative approach, they can unlock new levels of agility, responsiveness, and competitive advantage in an ever-evolving marketplace.

| Key Components | Benefits |

|---|---|

| Inventory Management Systems | Real-time tracking, automated replenishment, optimal inventory levels |

| Warehouse Automation | Increased productivity, accuracy, and speed in physical handling and movement of goods |

| Logistics Optimization | Route optimization, fleet performance monitoring, automated shipment coordination |

| Data Analytics Tools | Valuable insights, demand forecasting, data-driven decision making |

Inventory Management Systems

In today’s fast-paced business landscape, efficient inventory management systems have become crucial for maintaining a competitive edge. By harnessing the power of automation, companies can revolutionize their supply chain operations and achieve unprecedented levels of visibility and control.

Automated Inventory Tracking

Automated inventory management systems leverage cutting-edge technologies, such as RFID (Radio Frequency Identification) and barcode scanning, to provide real-time tracking of inventory levels. This advanced capability allows businesses to monitor their stock in real-time, ensuring that they can respond swiftly to changing demand and avoid stockouts.

Real-Time Inventory Visibility

Real-time inventory visibility is a game-changer for modern supply chains. By integrating automated inventory tracking with centralized data management, companies can access a comprehensive view of their available stock across multiple locations. This visibility empowers informed decision-making, enabling businesses to optimize their warehouse automation and streamline their logistics operations.

| Benefits of Automated Inventory Management | Improved Inventory Visibility |

|---|---|

|

|

By embracing advanced inventory management systems, businesses can unlock the full potential of their supply chain, driving increased efficiency, reduced costs, and enhanced customer satisfaction.

Warehouse Automation

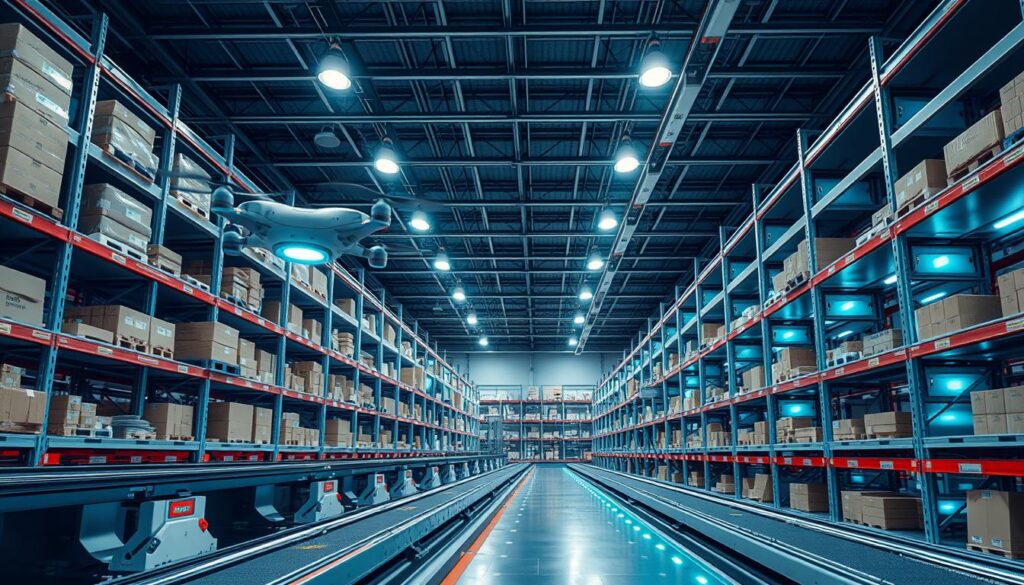

In the dynamic world of supply chain management, warehouse automation has emerged as a game-changing solution. By leveraging a range of cutting-edge technologies, businesses can streamline their warehouse operations, boost efficiency, and enhance overall productivity. Let’s explore the key aspects of warehouse automation that are transforming the industry.

Robotic Picking and Automated Storage

One of the primary pillars of warehouse automation is the integration of robotic picking systems. These advanced systems use sophisticated algorithms and sensors to locate, retrieve, and transport items with precision and speed, reducing the need for manual labor. Complementing this, automated storage and retrieval systems (AS/RS) optimize the use of warehouse space, enabling faster storage and retrieval of goods.

Transportation Management Integration

Warehouse automation also involves seamless integration with transportation management systems. By automating the coordination of inbound and outbound shipments, businesses can ensure smooth logistics, minimize delays, and enhance customer satisfaction. This level of integration enables real-time tracking, route optimization, and data-driven decision-making.

“Warehouse automation is the key to unlocking the full potential of your supply chain. By embracing these cutting-edge technologies, you can transform your operations, streamline workflows, and deliver unparalleled customer experiences.”

Optimization and Data-Driven Insights

At the heart of warehouse automation lies the power of data-driven insights. Advanced analytics and predictive modeling enable businesses to forecast demand, optimize inventory levels, and make informed decisions. This data-driven approach helps organizations anticipate changes, mitigate risks, and continuously improve their warehouse automation strategies.

As the supply chain landscape evolves, warehouse automation emerges as a strategic imperative. By leveraging these innovative technologies, businesses can enhance their operational efficiency, reduce costs, and deliver exceptional customer experiences. The future of supply chain management is automated, and the time to embrace this transformation is now.

How to Automate Supply Chain Management

Automating your supply chain management can streamline operations, improve efficiency, and enhance visibility across your entire logistics network. To get started, follow these key steps:

- Identify areas for automation: Analyze your current supply chain processes and pinpoint the most time-consuming, error-prone, or repetitive tasks that can be automated.

- Select the right technologies: Explore innovative solutions like inventory management systems, warehouse automation tools, transportation management software, and predictive analytics platforms to address your specific automation needs.

- Integrate your systems: Ensure seamless data flow and communication between your various supply chain systems to create a unified and responsive ecosystem.

- Implement change management strategies: Prepare your team for the transition by providing training, fostering a culture of innovation, and addressing any concerns or resistance to the new automated processes.

Automating your supply chain management can yield significant benefits, such as reduced operational costs, improved inventory visibility, enhanced customer satisfaction, and better decision-making capabilities. By embracing the right technologies and implementing a well-planned automation strategy, you can streamline your supply chain and gain a competitive edge in today’s fast-paced business landscape.

| Automation Technology | Key Benefits |

|---|---|

| Inventory Management Systems | Automated tracking, real-time visibility, and optimized inventory levels |

| Warehouse Automation | Increased efficiency, reduced errors, and improved throughput |

| Logistics Automation | Optimized transportation routes, automated dispatch, and improved delivery times |

| Predictive Analytics | Accurate demand forecasting, proactive decision-making, and enhanced supply chain resilience |

By leveraging these innovative technologies, you can streamline your how to automate supply chain management and gain a competitive edge in today’s fast-paced business environment.

“Automation is the key to unlocking the full potential of your supply chain. It’s not just about reducing manual tasks, but about gaining real-time visibility, making data-driven decisions, and driving continuous improvement.”

Logistics Automation

In the realm of supply chain management, logistics automation is a game-changer. By streamlining transportation processes, businesses can unlock a world of cost savings, improved delivery times, and enhanced customer satisfaction. From automated dispatch to intelligent route optimization, logistics automation is transforming the way companies manage their logistics operations.

Automated Transportation Management

One of the key benefits of logistics automation is automated transportation management. By integrating advanced software and algorithms, companies can automate the dispatch of their fleet, track vehicle locations in real-time, and optimize routing. This not only reduces the burden on logistics teams but also ensures efficient resource utilization and on-time deliveries.

Route Optimization

At the heart of logistics automation lies route optimization. Leveraging data-driven insights and artificial intelligence, companies can plan the most efficient routes for their transportation fleet. This not only reduces fuel costs and carbon footprint but also minimizes delivery times, ensuring customer satisfaction.

| Feature | Benefit |

|---|---|

| Automated Dispatch | Streamlined logistics operations, reduced manual intervention |

| Real-Time Fleet Tracking | Improved visibility, faster response to disruptions |

| Intelligent Route Optimization | Cost savings, reduced emissions, and on-time deliveries |

By embracing logistics automation, businesses can unlock a new era of efficiency, cost-effectiveness, and customer-centric transportation management. As the demand for logistics automation, transportation management, and route optimization continues to grow, companies that invest in these innovative solutions will be poised for success in the dynamic supply chain landscape.

ERP Integration

Integrating your supply chain automation solutions with your enterprise resource planning (ERP) system can be a game-changer for your business. This strategic integration streamlines your business processes, improves data accuracy, and enhances overall operational efficiency.

Streamlining Business Processes

By seamlessly connecting your ERP integration with your supply chain automation, you can eliminate manual data entry, reduce errors, and automate key workflows. This integration ensures that information flows effortlessly between your various systems, enabling real-time visibility and improved decision-making.

Some of the key benefits of ERP integration include:

- Streamlined order management, from placement to fulfillment

- Automated inventory tracking and replenishment

- Improved demand forecasting and production planning

- Enhanced visibility across the entire supply chain

When your ERP integration and supply chain automation work in harmony, you can expect increased efficiency, reduced operational costs, and better overall business performance.

“Integrating our ERP system with our supply chain automation solutions has been a game-changer for our business. We’ve seen a significant improvement in our operational efficiency and better visibility across our entire supply chain.”

Demand Forecasting

In the fast-paced world of supply chain management, demand forecasting has emerged as a critical component of automation. By leveraging advanced analytics and machine learning, businesses can now anticipate customer needs with greater accuracy, optimize inventory levels, and make more informed decisions that drive efficiency across their operations.

Accurate demand forecasting allows supply chain managers to proactively manage inventory, ensuring they have the right products in the right quantities at the right time. This not only reduces the risk of stock-outs and excess inventory but also enables companies to better align their production and distribution plans with customer demand.

| Key Benefits of Demand Forecasting | Impact |

|---|---|

| Improved Inventory Management | Reduce overstocking and stockouts |

| Optimized Production Planning | Align supply with anticipated demand |

| Enhanced Transportation and Logistics | Optimize delivery routes and schedules |

| Better Customer Service | Ensure product availability and on-time delivery |

By integrating demand forecasting into their supply chain automation strategies, businesses can unlock a wealth of benefits, from cost savings and increased efficiency to improved customer satisfaction and loyalty. As the technology continues to evolve, the role of demand forecasting in supply chain optimization will only become more crucial.

“Accurate demand forecasting is the backbone of a responsive and resilient supply chain. It empowers businesses to stay ahead of the curve and make data-driven decisions that drive sustainable growth.”

Predictive Analytics

In the dynamic landscape of modern supply chains, harnessing the power of predictive analytics has become a game-changer. By leveraging data-driven insights, businesses can optimize their operations, improve supply chain efficiency, and make informed decisions that drive growth.

Improving Supply Chain Efficiency

Predictive analytics enables supply chain managers to identify potential bottlenecks, anticipate fluctuations in demand, and proactively address issues before they arise. By using advanced algorithms and machine learning, businesses can forecast inventory needs, optimize transportation routes, and streamline warehouse operations, leading to cost savings and enhanced productivity.

Data-Driven Decision Making

The integration of predictive analytics in supply chain automation provides a clear competitive edge. With access to real-time data and AI-driven insights, businesses can make informed, data-driven decisions that align with their strategic objectives. This empowers them to respond quickly to market changes, adapt to customer preferences, and drive sustainable growth.

| Key Benefits of Predictive Analytics in Supply Chain | Impact on Business Performance |

|---|---|

| Improved inventory management | Reduced operational costs and increased profitability |

| Enhanced demand forecasting | Better alignment between supply and demand |

| Optimized transportation and logistics | Faster deliveries and improved customer satisfaction |

| Proactive risk mitigation | Increased supply chain resilience and agility |

By embracing the transformative power of predictive analytics, businesses can unlock new levels of supply chain efficiency and make data-driven decisions that propel their organizations forward in today’s competitive landscape.

IoT for Supply Chain

The Internet of Things (IoT) is transforming the way supply chains operate, providing unprecedented visibility and tracking capabilities. By integrating IoT-enabled technologies, businesses can revolutionize their supply chain management, delivering enhanced agility and responsiveness.

Enhancing Visibility and Tracking

IoT-powered sensors and devices can track the real-time location, status, and condition of assets throughout the supply chain. From raw materials to finished products, this data-driven approach offers complete visibility, enabling organizations to make informed decisions and respond swiftly to changing market demands.

IoT sensors can be attached to various supply chain components, such as containers, vehicles, and warehouses, providing detailed insights into the movement and performance of these assets. By monitoring factors like temperature, humidity, and shock, companies can ensure the integrity of their products and optimize their logistics operations.

| IoT-Enabled Supply Chain Benefits | Impact |

|---|---|

| Real-time asset tracking | Improved inventory management, reduced losses, and enhanced delivery reliability |

| Condition monitoring | Proactive maintenance, reduced spoilage, and increased product quality |

| Supply chain visibility | Streamlined operations, faster decision-making, and enhanced customer satisfaction |

By leveraging the power of IoT for supply chain management, organizations can unlock new levels of efficiency, agility, and responsiveness, ultimately driving improved business outcomes and customer experiences.

AI in Logistics

In the ever-evolving world of logistics, artificial intelligence (AI) is emerging as a game-changer. This cutting-edge technology is transforming the way supply chains operate, enabling a new era of intelligent automation. By harnessing the power of AI, logistics professionals can optimize transportation, streamline warehouse management, and make data-driven strategic decisions that drive efficiency and profitability.

Intelligent Automation: The AI Advantage

AI-powered solutions in logistics are revolutionizing the way businesses approach supply chain management. Intelligent automation leverages machine learning algorithms to automate repetitive tasks, such as inventory tracking, order processing, and route optimization. This not only reduces manual labor but also enhances accuracy and responsiveness, enabling logistics companies to stay ahead of the curve.

One of the key benefits of AI in logistics is the ability to make real-time, data-driven decisions. AI-powered systems can analyze vast amounts of data, identify patterns, and provide actionable insights that help logistics professionals make informed choices about everything from transportation routes to inventory management.

“AI is transforming the logistics industry, enabling businesses to streamline operations, improve customer service, and gain a competitive edge.”

Another aspect of intelligent automation in logistics is the integration of IoT (Internet of Things) devices. By connecting sensors and tracking devices throughout the supply chain, AI can provide unprecedented visibility and control, allowing for better inventory management, asset tracking, and fleet optimization.

As the logistics industry continues to evolve, the integration of AI in logistics will become increasingly crucial for businesses seeking to stay ahead of the curve. By embracing this transformative technology, logistics professionals can unlock new levels of efficiency, agility, and customer satisfaction.

Implementing Supply Chain Automation

Automating your supply chain can bring significant benefits, but the implementation process requires careful planning and execution. Successful supply chain automation involves navigating change management and addressing integration challenges to ensure a seamless transition.

Change Management

Implementing how to automate supply chain management often involves significant changes within an organization. Effective change management is crucial to ensure employee buy-in and a smooth rollout. This includes:

- Engaging stakeholders at all levels to understand their concerns and address them proactively

- Providing comprehensive training to equip employees with the necessary skills and knowledge

- Adopting a phased approach to allow for gradual implementation and feedback

- Communicating the benefits of automation to foster a culture of innovation and adaptability

Integration Challenges

One of the key integration challenges in supply chain automation is ensuring seamless integration between various systems and technologies. This may involve:

- Aligning legacy systems with new automation tools

- Establishing robust data management protocols to ensure data integrity and accessibility

- Addressing compatibility issues between different software platforms and hardware components

- Developing robust cybersecurity measures to protect against potential vulnerabilities

By navigating these change management strategies and integration challenges, organizations can successfully implement how to automate supply chain management and unlock the full potential of supply chain automation.

Supply Chain Automation Best Practices

Implementing supply chain automation can be a game-changer for businesses, but it’s crucial to follow best practices to ensure long-term success. By leveraging these proven strategies, you can maximize the benefits of supply chain automation and streamline your operations.

Prioritize Integration

Seamless integration is the foundation of effective supply chain automation. Ensure that your chosen solutions integrate seamlessly with your existing systems, from enterprise resource planning (ERP) to transportation management and beyond. This will enable a unified, data-driven approach to your supply chain operations.

Embrace Flexibility

Supply chains are dynamic, and your supply chain automation strategy should be flexible enough to adapt to changing market conditions, customer demands, and technological advancements. Invest in scalable solutions that can grow with your business and respond to emerging trends.

Foster Collaboration

Effective supply chain automation requires collaboration across departments and with external partners, such as suppliers and logistics providers. Foster a culture of transparency and open communication to ensure everyone is aligned and working towards common goals.

Prioritize Data Security

As you automate your supply chain, data security becomes increasingly critical. Implement robust cybersecurity measures to protect your sensitive information and safeguard your systems from potential threats.

Continuous Improvement

Embrace a mindset of continuous improvement. Regularly review your supply chain automation strategies, identify areas for optimization, and implement updates to ensure your operations remain efficient and effective.

| Best Practice | Key Benefits |

|---|---|

| Prioritize Integration | Enables a unified, data-driven approach to supply chain operations |

| Embrace Flexibility | Allows the supply chain automation strategy to adapt to changing conditions |

| Foster Collaboration | Promotes transparency and aligns all stakeholders towards common goals |

| Prioritize Data Security | Protects sensitive information and safeguards systems from potential threats |

| Continuous Improvement | Ensures supply chain automation strategies remain efficient and effective |

By implementing these best practices for supply chain automation, you can unlock the full potential of your automation efforts and drive significant improvements in efficiency, visibility, and overall supply chain performance.

Conclusion

As we’ve explored throughout this guide, the benefits of automating your supply chain are immense. From enhanced inventory management and warehouse optimization to data-driven decision-making and improved logistics, supply chain automation has the power to transform your business and drive sustainable growth.

By implementing the key components of supply chain automation, such as inventory management systems, warehouse automation, and logistics automation, you can streamline your operations, reduce costs, and enhance customer satisfaction. Integrating your enterprise resource planning (ERP) systems and leveraging predictive analytics and IoT technologies can further optimize your supply chain, giving you a competitive edge in the market.

The journey to supply chain automation may seem daunting, but with the right strategy, change management, and integration expertise, you can successfully implement these transformative solutions. Remember, the path to how to automate supply chain management is not a one-size-fits-all approach, but one that requires careful planning and adaptation to your unique business needs. With supply chain automation, the possibilities for improved efficiency, agility, and profitability are endless. Take the first step and explore the innovative solutions that can propel your business forward.