Managing inventory can be a complex and time-consuming task, but with the right automation solutions, you can streamline your processes and gain better control over your stock. In this comprehensive guide, we’ll explore how to automate your inventory management to improve operational efficiency, reduce manual errors, and optimize your supply chain.

Key Takeaways

- Discover the benefits of automating your inventory management processes

- Understand the key features of inventory automation software solutions

- Learn how to optimize your warehouse operations with automated systems

- Explore strategies for improving inventory forecasting and replenishment

- Gain insights into choosing the right inventory automation software for your business

Importance of Automating Inventory Management

In today’s fast-paced business landscape, automated inventory tracking has become a game-changer for companies seeking to streamline their operations and gain a competitive edge. By leveraging the power of automation, businesses can eliminate the time-consuming manual processes and reduce the risk of costly errors that plague traditional inventory management methods.

Eliminate Manual Processes and Errors

Manual inventory tracking often involves tedious paperwork, inaccurate data entry, and the potential for human error. Automated inventory tracking systems, on the other hand, provide real-time visibility into your stock levels, reducing the likelihood of stockouts, overstocking, and inaccurate reporting. This not only saves time and resources but also ensures that your business maintains a tight grip on its inventory, leading to improved customer satisfaction and reduced operational costs.

Improve Operational Efficiency

By automating your inventory management, you can unlock a world of inventory optimization possibilities. With access to real-time inventory visibility, you can make more informed decisions about order placement, product replenishment, and resource allocation. This, in turn, leads to enhanced operational efficiency, streamlined workflows, and the ability to respond quickly to changing market demands.

“Automating our inventory management has been a game-changer for our business. We’ve seen a significant reduction in manual processes, improved accuracy, and better decision-making capabilities. The benefits of this investment have been felt across our entire organization.”

In conclusion, the importance of automating inventory management cannot be overstated. By leveraging the power of technology, businesses can eliminate manual errors, optimize their operations, and gain a competitive edge in today’s dynamic market. As the demand for efficient and data-driven inventory management continues to grow, investing in automated inventory tracking solutions is a strategic move that can unlock unprecedented levels of inventory optimization and real-time inventory visibility.

Understanding Inventory Automation Software

In today’s fast-paced business environment, inventory management has become a critical component of operational efficiency. Inventory automation software is designed to streamline this process, providing businesses with the tools they need to optimize their stock control and improve overall productivity.

These advanced solutions leverage cutting-edge technologies, such as barcoding, RFID (Radio Frequency Identification), and AI-powered analytics, to deliver real-time visibility and control over your inventory. By automating various tasks, from tracking and monitoring stock levels to forecasting and replenishment, inventory automation software helps eliminate manual processes and reduce the risk of errors.

One of the key benefits of these systems is their ability to integrate seamlessly with other business software, such as enterprise resource planning (ERP) and warehouse management systems (WMS). This integration ensures a seamless flow of information, allowing businesses to make informed decisions based on comprehensive data.

| Feature | Benefit |

|---|---|

| Real-Time Inventory Tracking | Provides instant visibility into stock levels, reducing the risk of stockouts and overstock |

| Automated Replenishment | Triggers reorders based on predefined thresholds, ensuring optimal inventory levels |

| Advanced Reporting and Analytics | Offers data-driven insights to support strategic decision-making and improve inventory planning |

By adopting inventory automation software, businesses can streamline their stock control automation processes, enhance operational efficiency, and ultimately, drive greater profitability and growth.

Key Features of Inventory Automation Solutions

Inventory automation solutions are revolutionizing the way businesses manage their stock. At the core of these advanced systems are two powerful capabilities: real-time inventory tracking and seamless integration with barcoding and RFID technologies.

Real-Time Inventory Visibility

With real-time inventory visibility, businesses can monitor their stock levels, movements, and transactions in real-time. This allows for accurate, up-to-the-minute data on the availability and location of products, enabling better decision-making and responsiveness to customer demands. By leveraging this real-time real-time inventory visibility, organizations can optimize their supply chain and minimize the risk of stockouts or overstocking.

Barcoding and RFID Integration

Inventory automation solutions often integrate with barcoding and RFID (Radio Frequency Identification) technologies, providing a comprehensive and efficient way to track and manage inventory. Barcoding and RFID solutions enable automated data capture, reducing the need for manual data entry and minimizing the potential for human errors. This integration streamlines the entire inventory process, from receiving and stocking to order fulfillment and reporting.

| Feature | Benefits |

|---|---|

| Real-Time Inventory Visibility |

|

| Barcoding and RFID Integration |

|

“Inventory automation solutions empower businesses to achieve unprecedented levels of real-time inventory visibility and operational efficiency.”

Streamlining Stock Control with Automation

Automating your stock control processes can significantly improve efficiency and accuracy. Inventory automation solutions can automate tasks like order processing, warehouse management, and inventory replenishment, helping you maintain optimal stock levels and reduce the risk of stockouts or overstock.

One of the key benefits of stock control automation is improved visibility and control over your inventory. With real-time tracking and reporting, you can easily monitor stock levels, identify trends, and make informed decisions about purchasing and restocking. This helps you avoid the common pitfalls of manual inventory management, such as human errors, delayed updates, and lack of data-driven insights.

Furthermore, automated warehouse management systems can optimize your storage and fulfillment processes, ensuring efficient product handling and streamlined order processing. By integrating barcoding or RFID technology, you can automate tasks like item identification, location tracking, and inventory updates, reducing the time and resources required to manage your stock.

“Automating our stock control has been a game-changer for our business. We’ve seen a significant reduction in errors, improved inventory visibility, and better-informed decision-making.”

– Sarah, Retail Manager

When it comes to stock control automation, the key is to select a solution that aligns with your specific business needs and operational requirements. Look for features like real-time inventory tracking, automated ordering and replenishment, and seamless integration with your existing systems and workflows.

By embracing automated warehouse management and stock control automation, you can streamline your inventory processes, reduce operational costs, and enhance your overall business efficiency. Invest in the right technology and unlock the full potential of your supply chain.

How to Automate Inventory Management

Automating your inventory management process can be a game-changer for your business. By leveraging inventory management system technologies, you can streamline operations, reduce manual errors, and gain real-time visibility into your stock levels. Here’s a step-by-step guide to help you get started:

- Evaluate Your Current Inventory Management Processes: Start by assessing your existing inventory management practices. Identify areas where manual processes can be automated, such as data entry, stock tracking, and reordering.

- Research Inventory Automation Solutions: Explore the market for how to automate inventory management software and technologies that align with your business needs. Look for features like barcode scanning, RFID integration, and predictive analytics.

- Implement the Right Inventory Automation Tools: Select the inventory management system that best suits your requirements, considering factors like scalability, integration capabilities, and user-friendliness.

- Integrate Automation into Your Existing Workflows: Seamlessly integrate the new inventory automation tools into your existing processes, ensuring a smooth transition and minimizing disruptions.

- Train Your Team: Provide comprehensive training to your employees on the new inventory automation system, empowering them to leverage the technology effectively.

- Monitor and Optimize: Continuously monitor the performance of your automated inventory management system, making adjustments as needed to ensure maximum efficiency and cost-savings.

By following these steps, you can successfully automate inventory management and unlock the full potential of your inventory operations.

“Automating inventory management is not just about technology; it’s about transforming your entire business approach to inventory control.”

| Feature | Benefit |

|---|---|

| Real-Time Inventory Tracking | Gain immediate visibility into stock levels, reducing the risk of stockouts and overstocking. |

| Automated Reordering | Trigger replenishment orders based on predefined thresholds, ensuring optimal inventory levels. |

| Predictive Analytics | Use data-driven insights to forecast demand and optimize inventory planning. |

Automated Warehouse Management Systems

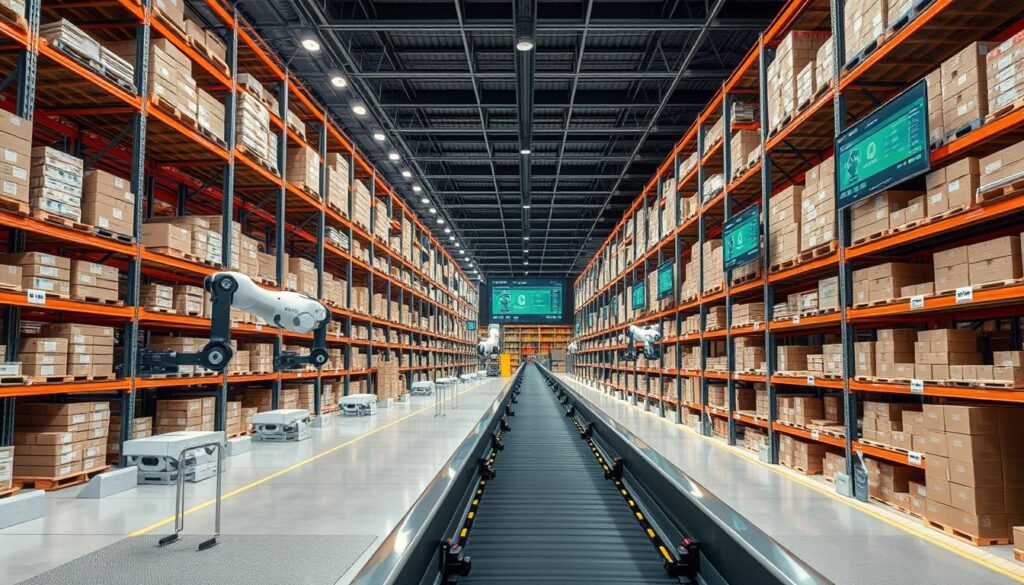

Automated warehouse management systems (WMS) play a pivotal role in streamlining inventory management processes. These sophisticated solutions optimize warehouse operations by automating critical tasks, from receiving and storage to picking and shipping. By integrating with other inventory management systems, automated WMS provide end-to-end visibility and control, empowering businesses to make data-driven decisions and enhance overall operational efficiency.

Optimizing Warehouse Operations

Automated WMS automate a wide range of warehouse activities, reducing the burden of manual processes and minimizing the risk of human error. These systems handle tasks such as receiving, put-away, stock location, order picking, and order packing with precision and speed, ensuring accurate inventory tracking and fulfillment.

Integrating Automated Systems

Seamless integration with other inventory management systems, such as enterprise resource planning (ERP) and customer relationship management (CRM) platforms, is a hallmark of advanced automated WMS. This integration enables real-time data sharing, providing a comprehensive view of inventory levels, stock movements, and customer orders. By combining these capabilities, businesses can make informed decisions, optimize inventory levels, and enhance customer satisfaction.

| Feature | Benefits |

|---|---|

| Automated Receiving and Putaway | Streamline the flow of incoming goods, improve accuracy, and minimize handling time. |

| Real-Time Inventory Tracking | Gain instant visibility into stock levels, locations, and movements, enabling better informed decisions. |

| Intelligent Order Picking | Optimize the picking process, reducing labor costs and improving order fulfillment accuracy. |

| Automated Shipping and Packing | Expedite the outbound process, ensuring timely and accurate order deliveries. |

By embracing automated warehouse management systems, businesses can unlock a new level of operational efficiency, driving cost savings, improved accuracy, and enhanced customer satisfaction. These intelligent solutions are transforming the way companies manage their inventory, setting the stage for a more agile and responsive supply chain.

Inventory Forecasting and Replenishment

In the dynamic world of inventory management, the ability to accurately forecast demand and replenish stock efficiently is crucial. Automated inventory forecasting and replenishment solutions harness the power of predictive analytics and AI-driven demand planning to revolutionize the way businesses manage their inventory levels.

Predictive Analytics for Demand Planning

By leveraging advanced predictive analytics, inventory automation software can analyze historical sales data, market trends, and other relevant factors to forecast future demand. This allows businesses to anticipate customer needs and make informed decisions about inventory replenishment, minimizing the risk of stockouts or excess inventory.

Automated demand planning algorithms can identify patterns, seasonal fluctuations, and other market dynamics, enabling businesses to proactively adjust their inventory levels to meet evolving customer demands. This level of precision helps optimize inventory forecasting and replenishment, ensuring that the right products are available at the right time, ultimately improving customer satisfaction and operational efficiency.

“Automating inventory forecasting and replenishment is a game-changer for businesses looking to streamline their supply chain and maintain a competitive edge.”

Integrating inventory optimization strategies with these predictive capabilities empowers businesses to fine-tune their inventory levels, minimize carrying costs, and enhance their overall financial performance.

Benefits of Automated Inventory Tracking

The implementation of automated inventory tracking solutions offers a multitude of advantages for businesses. By continuously monitoring inventory levels in real-time, these systems provide unparalleled visibility and control over your stock, enabling you to make more informed decisions and optimize your supply chain.

Improved Visibility and Control

One of the primary benefits of automated inventory tracking is the enhanced visibility it provides. With real-time data on stock levels, item locations, and product movements, you can stay on top of your inventory like never before. This improved real-time inventory visibility allows you to make better-informed decisions, anticipate potential stockouts, and respond quickly to changes in demand or supply.

- Gain complete oversight of your inventory, from raw materials to finished goods

- Eliminate guesswork and make data-driven decisions to optimize inventory levels

- Quickly identify and address discrepancies, ensuring accurate stock counts

Moreover, automated inventory tracking empowers you to exercise tighter control over your inventory management processes. By automating routine tasks such as order processing, stock replenishment, and cycle counting, you can reduce the risk of human error and streamline your operations for greater efficiency.

“Automated inventory tracking systems have revolutionized the way we manage our stock. The real-time visibility and control they provide are invaluable in keeping our operations running smoothly and our customers satisfied.”

– Jane Doe, Inventory Manager at ABC Corporation

| Key Benefits of Automated Inventory Tracking | Impact |

|---|---|

| Improved Visibility | Gain complete oversight of inventory levels, item locations, and product movements |

| Enhanced Control | Automate routine tasks, reduce errors, and streamline inventory management processes |

| Optimized Supply Chain | Make data-driven decisions to maintain optimal inventory levels and minimize stockouts |

| Increased Efficiency | Improve operational efficiency and responsiveness to changes in demand or supply |

Inventory Optimization Strategies

Effective inventory optimization is essential for businesses aiming to streamline their operations and maintain a competitive edge. By leveraging data-driven strategies and automation, companies can optimize their inventory levels, reduce carrying costs, and enhance overall efficiency. In this section, we’ll explore key techniques that can help you optimize your inventory and drive business success.

Demand Forecasting: Predicting Future Needs

Accurate demand forecasting is a cornerstone of effective inventory optimization. By analyzing historical sales data, market trends, and other relevant factors, businesses can anticipate future demand and adjust their inventory accordingly. This helps avoid stockouts and minimize excess inventory, leading to cost savings and improved customer satisfaction.

Safety Stock Management: Ensuring Uninterrupted Supply

Maintaining the right level of safety stock is crucial for mitigating the impact of unexpected fluctuations in demand or supply. By carefully calculating and managing safety stock levels, companies can ensure a continuous flow of products, preventing stockouts and minimizing the risk of lost sales.

Inventory Segmentation: Categorizing for Optimal Management

Dividing your inventory into distinct categories based on factors such as sales volume, profitability, or lead time can help you optimize your inventory optimization strategies. This approach allows you to prioritize the management of high-value or fast-moving items, ensuring that your resources are allocated effectively.

“Effective inventory optimization is not just a cost-cutting measure – it’s a strategic investment that can drive long-term success and growth for your business.”

By implementing these inventory optimization strategies, businesses can achieve a delicate balance between meeting customer demand and maintaining lean, efficient inventory levels. This, in turn, leads to improved cash flow, reduced overhead costs, and enhanced overall operational performance.

Choosing the Right Inventory Automation Software

Selecting the appropriate inventory automation software is crucial for the success of your inventory management efforts. When evaluating potential solutions, it’s essential to consider your business needs and ensure the software can scale and integrate seamlessly with your existing systems.

Evaluating Your Business Needs

Begin by assessing your current inventory management challenges and pain points. What specific features and functionalities do you require to streamline your operations? Consider factors such as the size and complexity of your inventory, the number of SKUs, and the frequency of transactions. This will help you identify the key capabilities you need in an inventory automation software.

Scalability and Integration Capabilities

As your business grows, your inventory automation software must be able to scale to accommodate your evolving needs. Look for solutions that offer flexible, modular architectures, allowing you to add new features and functionalities as required. Additionally, ensure the software can seamlessly integrate with your existing enterprise resource planning (ERP) system, accounting software, and other critical business applications, ensuring a seamless flow of data and efficient information sharing.

| Feature | Requirement |

|---|---|

| Real-Time Inventory Tracking | Ability to monitor stock levels and product movements in real-time, across multiple locations |

| Automated Replenishment | Intelligent forecasting and reordering capabilities to maintain optimal inventory levels |

| Barcode and RFID Integration | Streamlined inventory data capture and management through the use of barcodes and RFID technology |

| Reporting and Analytics | Comprehensive reporting and business intelligence tools to support data-driven decision-making |

By carefully evaluating your business needs and assessing the scalability and integration capabilities of different inventory automation software solutions, you can make an informed decision and select the best fit for your organization.

“Selecting the right inventory automation software can be a game-changer for your business, streamlining operations and empowering data-driven decision-making.”

Implementing Inventory Automation Solutions

Automating inventory management is a strategic move that can revolutionize your business operations. However, the implementation process requires careful planning and execution to ensure a seamless transition. The key to successful inventory automation lies in effectively managing the change and providing comprehensive training to your employees.

Change Management and Training

Implementing an inventory automation system involves more than just installing software. It requires a well-thought-out change management strategy to address the potential resistance from your team. Effective communication, employee engagement, and comprehensive training are crucial components of this process. By involving your employees in the transition and providing them with the necessary skills and knowledge, you can foster a sense of ownership and ensure maximum adoption of the new inventory management system.

- Develop a clear communication plan to inform and engage your employees about the upcoming changes.

- Provide comprehensive training programs to equip your team with the necessary skills to navigate the new how to automate inventory management system.

- Assign dedicated champions within your organization to support the implementation and address any concerns or questions from your employees.

- Continuously gather feedback and adapt your approach to address any challenges or pain points that arise during the implementation phase.

By prioritizing change management and employee training, you can ensure a smooth transition to your new inventory management system and unlock the full potential of your how to automate inventory management solution.

“Successful implementation of inventory automation requires a holistic approach that addresses both the technological and the human aspects of the change.”

| Key Considerations for Implementing Inventory Automation | Benefits |

|---|---|

| Change Management and Employee Training | Ensures smooth transition and maximum adoption of the new system |

| Integration with Existing Processes and Systems | Seamless data flow and optimization of overall operations |

| Scalability and Future Upgrades | Allows for business growth and adaptation to evolving needs |

| Continuous Monitoring and Optimization | Enhances efficiency and identifies areas for further improvement |

Best Practices for Inventory Automation

Automating your inventory management is a powerful way to streamline your operations and optimize your inventory levels. To achieve the full benefits of inventory optimization and how to automate inventory management, it’s crucial to follow best practices. Let’s explore some proven strategies that can help you effectively implement and maintain your inventory automation solution.

Ensure Data Accuracy

Accurate and up-to-date data is the foundation of effective inventory automation. Implement robust data collection processes, such as barcode scanning and RFID integration, to ensure that your inventory records reflect the true state of your stock. Regular audits and reconciliation can help identify and resolve any discrepancies.

Establish Performance Metrics

Develop a set of key performance indicators (KPIs) to measure the success of your inventory automation efforts. This may include metrics like inventory turnover, stock-out rates, and inventory holding costs. Regularly review these KPIs and use the insights to optimize your processes.

Continuous Optimization

- Regularly review your inventory automation processes and identify areas for improvement.

- Analyze inventory data to detect trends and patterns, and adjust your strategies accordingly.

- Stay informed about the latest advancements in inventory automation technology and consider upgrading your systems as needed.

By following these best practices, you can ensure that your how to automate inventory management and inventory optimization efforts deliver the maximum benefits to your business, from improved operational efficiency to better customer service and increased profitability.

“Implementing inventory automation is not a one-time event, but rather a continuous process of improvement and optimization.”

Overcoming Challenges in Inventory Automation

Automating your inventory management system can revolutionize your business operations, but it’s not without its challenges. As you embark on this transformative journey, it’s essential to be aware of the potential obstacles and have strategies in place to overcome them.

One of the primary hurdles businesses face is integrating automated systems with existing infrastructure. Ensuring seamless data flow and compatibility between various software and hardware components can be a complex undertaking. To navigate this challenge, it’s crucial to work closely with your technology partner, conduct thorough system assessments, and develop a comprehensive integration plan.

Another common issue is maintaining data quality and accuracy. Automated inventory management systems rely heavily on reliable data, and any discrepancies or inaccuracies can lead to suboptimal decision-making. Implementing robust data validation processes, regular audits, and employee training can help mitigate these concerns.

- Resistance to change can also impede the successful adoption of inventory automation. Employees may be hesitant to embrace new technologies, fearing the disruption to their established workflows. Effective change management strategies, such as providing comprehensive training, fostering a culture of innovation, and involving stakeholders in the implementation process, can help overcome this challenge.

- Budget constraints and the perceived high cost of implementing automated systems can also be a barrier. However, by conducting a thorough cost-benefit analysis and highlighting the long-term operational efficiencies and cost savings, you can build a compelling business case for investing in inventory management automation.

Remember, overcoming the challenges in inventory automation requires a multifaceted approach that combines strategic planning, effective change management, and a willingness to adapt to new technologies. By addressing these hurdles head-on, you can unlock the true potential of automated inventory management and propel your business towards greater success.

Conclusion

In conclusion, automating your inventory management processes can provide substantial benefits, including enhanced efficiency, better control over your stock, and improved decision-making capabilities. By leveraging the right inventory automation software and following best practices, you can streamline your operations, optimize your inventory, and gain a competitive edge in your market.

The journey towards how to automate inventory management may seem daunting, but with the right strategy and tools, it can become a game-changer for your business. Inventory automation solutions offer real-time tracking, barcoding and RFID integration, and predictive analytics, empowering you to make informed decisions and stay ahead of the curve.

As you embark on this transformative path, remember that effective implementation and change management are key. By involving your team, providing comprehensive training, and continuously refining your processes, you can unlock the full potential of inventory automation software and drive your business to new heights of success.